Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Noticias

Aquí, puedes describir un texto que quieres expresar

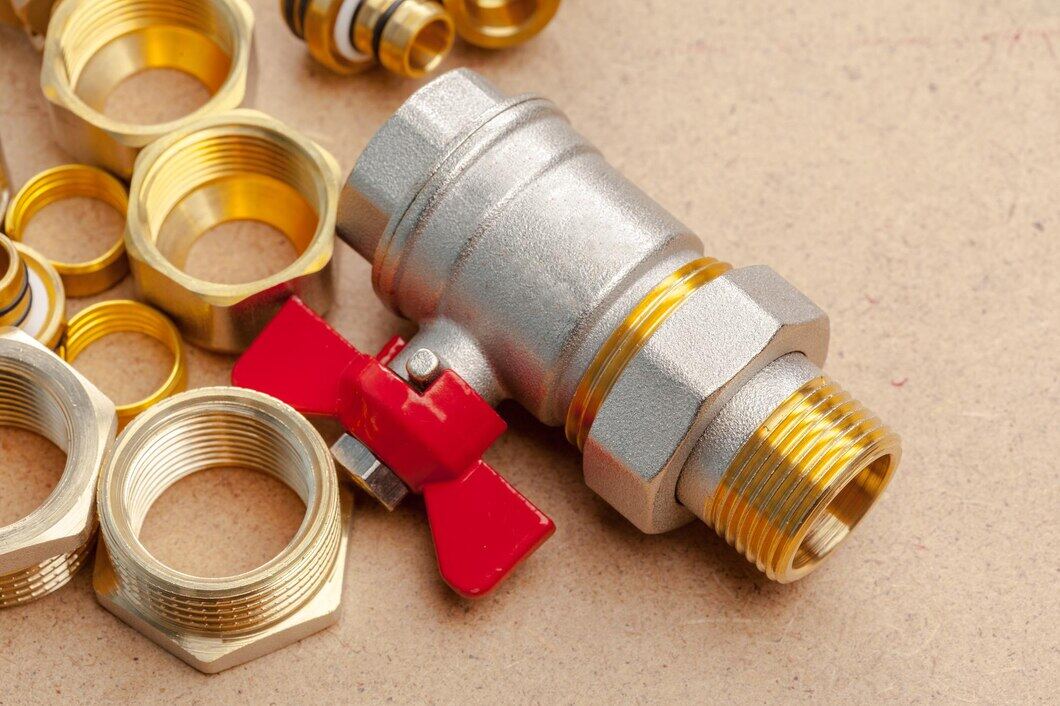

Navigating the World of Industrial Hose Fittings Manufacturer: Quality, Precision, and Reliability

In the vast landscape of industrial components, the role of an industrial hose fittings manufacturer cannot be overstated. These manufacturers are the backbone of countless industries, providing the essential parts that keep machinery running smoothly and efficiently. From the high-pressure demands of hydraulic systems to the precise requirements of pipeline connections, the quality of hose fittings is paramount. In this blog post, we will explore the intricacies of what makes a top-tier industrial hose fittings manufacturer, delve into the variety of fittings they offer, and discuss the importance of choosing the right supplier for your industrial needs.

Chapter 1: The Importance of Industrial Hose Fittings

Industrial hose fittings are more than just simple connectors; they are critical components in a wide array of systems. They must withstand extreme pressures, temperatures, and corrosive substances while maintaining a leak-proof seal. A reliable industrial hose fittings manufacturer understands these challenges and designs their products accordingly, ensuring that each fitting meets the rigorous standards required for industrial applications.

Chapter 2: The Range of Hose Fittings Offered by Manufacturers

A leading industrial hose fittings manufacturer offers a diverse range of products to cater to various industries. These include pipeline connection couplings, which are designed to connect and disconnect pipelines quickly and securely without the need for tools. Hydraulic hose fittings are another crucial category, especially those sourced from hydraulic hose fittings from China, known for their precision engineering and cost-effectiveness.

Chapter 3: Custom Solutions from OEM Flexible Sprinkler Hose Fittings

When it comes to fire safety, every second counts, and the reliability of a fire suppression system hinges on the quality of its components. OEM flexible sprinkler hose fittings are a critical part of these systems, connecting the sprinkler heads to the piping. An manufacturer that offers custom OEM solutions is invaluable to the fire safety industry. These manufacturers provide a service that goes beyond mere product supply; they collaborate with clients to understand the unique requirements of their fire suppression systems.

Customization begins with a thorough analysis of the client’s needs, including the type of building, the potential fire hazards, and the specific design of the fire suppression system. The industrial hose fittings manufacturer then uses this information to engineer fittings that are not only compliant with the latest safety standards but also tailored to fit the system’s design perfectly. This might involve creating fittings with unique angles, lengths, or diameters that aren’t available off the shelf.

The benefits of custom OEM fittings are manifold. They ensure a seamless fit, reducing the risk of leaks or malfunctions in the event of a fire. They can also simplify the installation process, saving time and labor costs. Moreover, by working with a manufacturer capable of producing these custom solutions, clients can rest assured that their fire suppression systems will perform optimally when needed the most.

Chapter 4: The Reusable Hydraulic Hose Fittings Factory Advantage

Hydraulic systems are the lifeblood of many industrial operations, and the fittings that connect the various components of these systems must withstand intense pressure and wear. However, when it comes time for maintenance or system modification, the ability to reuse fittings can be a game-changer. A reusable hydraulic hose fittings factory specializes in creating fittings that can be disconnected and reconnected multiple times without compromising the integrity of the connection.

These reusable fittings are designed with ease of assembly and disassembly in mind, often featuring simple screw-on mechanisms that do not require crimping. This design not only makes them reusable but also allows for quick repairs and modifications in the field, minimizing downtime. For businesses, this translates to significant cost savings, as the need to purchase new fittings every time a system is altered is eliminated.

Moreover, the environmental impact of reusable fittings is considerably lower. By reducing the need for new parts, these fittings contribute to waste reduction and promote a more sustainable approach to industrial operations. A factory that produces high-quality reusable hydraulic hose fittings is therefore not just providing a cost-effective solution but is also helping businesses move towards greener practices.

Chapter 5: Partnering with Hydraulic Tubes and Fittings LLC

In the world of hydraulics, compatibility and quality are paramount. A mismatched fitting can lead to leaks, system failures, and potentially hazardous situations. This is where a partnership with a company can be incredibly beneficial. Such a company offers a wide array of hydraulic components, ensuring that every part of a hydraulic system is perfectly matched and up to the task.

A reputable manufacturer will recognize the value of such partnerships. By collaborating with specialists in hydraulic components, they can offer their clients a one-stop-shop experience. Clients no longer need to source their parts from multiple suppliers, which can lead to compatibility issues and increased procurement complexity. Instead, they can rely on a single, trusted source for all their hydraulic needs.

The partnership between a manufacturer and a company is built on a foundation of shared expertise and commitment to quality. Together, they can provide comprehensive solutions that encompass everything from the initial system design to the supply of fittings and tubes, all the way to after-sales support. This collaborative approach not only streamlines the procurement process but also ensures that the hydraulic systems are built to last, with every component working in harmony to deliver optimal performance.

Chapter 6: The Manufacturing Process: Precision and Quality Control

The manufacturing process of industrial hose fittings is a testament to precision engineering. From the initial design phase to the final quality control checks, each step is meticulously carried out to ensure the highest quality product. An industrial hose fittings manufacturer must employ advanced manufacturing techniques, such as CNC machining and forging, to produce fittings that meet exact specifications.

Chapter 7: Material Selection for Optimal Performance

The choice of material is critical in the production of industrial hose fittings. Materials must be selected based on their strength, durability, and resistance to the elements they will be exposed to. Whether it’s stainless steel for corrosion resistance or brass for its malleability, an industrial hose fittings manufacturer must have expertise in material science to choose the best material for each application.

Chapter 8: The Role of Certifications and Standards

Certifications and industry standards are the benchmarks that ensure the reliability and safety of industrial hose fittings. A trusted industrial hose fittings manufacturer will adhere to international standards such as ISO, SAE, and DIN, and will have their products certified by recognized bodies. These certifications are not just a formality; they are a promise of quality and reliability to the customer.

Chapter 9: The Future of Industrial Hose Fittings Manufacturing

The future of industrial hose fittings manufacturing is shaped by technological advancements and the evolving needs of industries. A manufacturer must stay ahead of the curve, investing in research and development to innovate and improve their products. The integration of smart technologies and the push towards more sustainable manufacturing practices are just some of the trends that will define the future of hose fittings manufacturing.

Conclusion:

The role of an industrial hose fittings manufacturer is crucial in the seamless operation of industrial machinery and systems. From pipeline connection couplings to hydraulic hose fittings sourced from China, and from OEM flexible sprinkler hose fittings to the offerings of a reusable hydraulic hose fittings factory, these manufacturers provide the components that ensure efficiency and safety in industrial operations. By understanding the manufacturing process, material selection, and the importance of certifications, businesses can make informed decisions when choosing a manufacturer for their industrial hose fitting needs. As for one of leading industrial hose fittings manufacturers, we support various custom options to meet your specific needs!